Have you ever wondered what actually happens when you tap the brakes on a modern car? Does a simple cable pull a lever, or is something more intelligent at play? Imagine a silent, lightning-fast worker tucked away inside your car’s chassis. This worker takes a digital whisper from the computer and turns it into powerful, physical motion in milliseconds. Without this hidden strength, your car would be little more than a heavy rolling box. These tiny powerhouses are the reason your drive feels so smooth, and your stops feel so precise. Electric Vehicle Actuator is the core component that bridges the gap between software and the road.

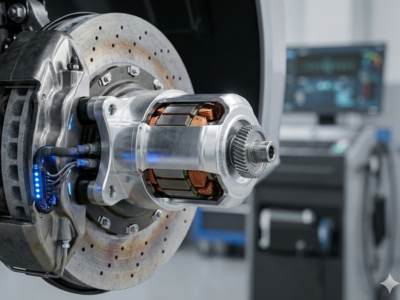

An Electric Vehicle Actuator turns electrical control signals into precise mechanical movement. These devices move your brakes, open cooling valves, and adjust suspension dampers. They also help the vehicle’s brain control motor torque and speed with extreme accuracy. When you steer or stop, you are trusting these components with your life.

Why These Silent Workers Define the Modern Drive

The current state of the Electric Vehicle Actuator market in 2026 is defined by a massive shift toward “X-by-Wire” technology. What used to be a niche category for luxury cars is now a standard requirement for all EVs. This growth is fueled by the move away from bulky hydraulic systems toward sleeker, electronic controls. Experts at the Department of Energy (DOE) note that as we push for longer range, every milligram of weight matters.

Today, the industry is moving toward integrated power electronics. This means actuators are getting smaller, smarter, and more efficient. For most manufacturers, 2026 is the year that high-performance actuators moved from experimental prototypes to essential mass-market hardware. These systems provide the “mechanical muscle” that allows an EV to handle like a sports car while maintaining the efficiency of a commuter.

The Science of Motion: How They Keep You Moving

A deep dive into the Electric Vehicle Actuator landscape reveals that the industry is at a critical strategic tipping point. The “digitalization of motion” is no longer just a trend; it is a necessity for autonomous driving features. Analysis shows that the speed of an actuator can be the difference between a near-miss and a collision.

The Strategic Competitive Edge:

- Braking Precision: Electro-mechanical brake actuators deliver faster clamping force than old hydraulic lines.

- Thermal Management: Smart valves route coolant to the battery or motor exactly when needed. This protects the inverter and prevents power loss.

- Chassis Control: Electronic Stability Control (ESC) uses actuators to pulse brakes individually. This prevents rollovers and keeps you on the road during a skid.

- Material Innovation: The push for non-rare-earth magnets in actuator motors is reducing supply chain risks for major brands.

The Main Types of Actuators You Rely On

Every time you get behind the wheel, dozens of actuators spring into action. Understanding their roles helps you appreciate the complexity of your EV.

- Brake Actuators: These are the most critical for safety. They power the ABS and traction control systems. They must meet strict NHTSA performance standards to ensure they never fail under pressure.

- Thermal and HVAC Actuators: These move the flaps and pumps that keep your battery at the perfect temperature. This is vital for maintaining your range and long-term battery health.

- Steering Actuators: In “Steer-by-Wire” systems, these replace the physical steering column. They provide feedback to the driver while allowing the computer to make micro-adjustments for safety.

Safety Standards and Global Regulations

You cannot build or buy an Electric Vehicle Actuator without a firm grasp of the safety rules. Regulators like NHTSA and the EU have set high bars for performance.

- ISO 26262: This is the gold standard for “Functional Safety.” It ensures that if an electronic component fails, the car remains in a safe state.

- FMVSS Standards: The Federal Motor Vehicle Safety Standards define how brakes and steering must perform. Every actuator must pass rigorous “malfunction telltale” tests.

- The EU Safety Mandate: New European rules require advanced driver assistance systems (ADAS) on all new vehicles. These systems depend entirely on high-speed actuators.

Materials and Design: The Science of Motion

The design of a modern Electric Vehicle Actuator is a balancing act. Engineers must juggle weight, noise, and heat.

- Magnetic Density: Using rare-earth magnets allows for smaller, more powerful motors. However, supply chain issues are leading many to explore alternative materials.

- High-Temp Capacitors: These allow actuators to work near a hot motor without failing.

- Wide-Bandgap Devices: Inverters using these new materials improve efficiency. They also reduce the cooling load on the actuators.

EV Ownership: What Actuators Do for You

As an EV owner, you might never see your actuators, but you feel them every day. They support the “behind the scenes” magic of electric driving.

- Charging Health: Thermal actuators manage the heat generated during Level 2 or DC fast charging. This prevents “throttling” and gets you back on the road faster.

- Regenerative Braking: Actuators blend the friction brakes with motor braking seamlessly. This makes your stops feel natural while recovering energy for the battery.

- Quiet Comfort: Unlike hydraulic pumps, electronic actuators are nearly silent. This preserves the “library-quiet” cabin experience that EV drivers love.

Actionable Checklist for Buying or Specifying

If you are involved in the automotive industry or just a curious buyer, use this checklist to judge actuator quality:

- Check for ISO 26262 Compliance: This proves the system was designed with safety as the first priority.

- Verify Thermal Limits: Can the actuator handle the extreme cold of winter and the heat of fast charging?

- Audit Diagnostic Coverage: Does the system have sensors to “self-check” for errors before they become problems?

- Confirm FMVSS Alignment: Ensure all braking and steering components meet local government safety mandates.

- Assess Material Source: Look for manufacturers who are moving toward sustainable, non-critical materials.

Answers to Your Top Questions

Is “Brake-by-Wire” safer than traditional brakes?

Yes, because it reacts much faster. It allows the safety systems to pulse the brakes hundreds of times per second with perfect accuracy.

Do actuators drain my battery?

They use very little power compared to the main traction motor. In fact, their efficiency in managing heat actually helps extend your total driving range.

What happens if a steering actuator loses power?

Global standards require “fail-safe” or “fail-operational” designs. This means there is always a backup power source or a secondary mechanical path to keep you in control.

The Bottom Line: Precision in Every Turn

The evolution of the Electric Vehicle Actuator is about one thing: removing the delay between thought and action. Whether it is a safety system saving you from a skid or a thermal valve protecting your battery, these machines are the silent fixers. By 2026, the most successful EVs will be those with the smartest, most resilient actuators. Success in the EV era demands strong engineering, transparent safety standards, and a focus on the driver. With these components in place, your car won’t just move; it will glide.